Blog / Insights

Explore how Bravura-AI solves real-world problems with smart solutions. Each article shows our impact through data-driven AI strategies.

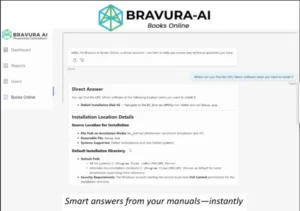

Bravura-AI Books Online: Turn Static Documentation into Active Intelligence

Every industrial organization sits on a hidden goldmine: shelves and servers filled with licensed documentation—operator manuals, vendor guides, and complex standards. Yet when an engineer

Why AI-Discovered Drugs Fail Without Data Unity

The pharmaceutical industry stands at a pivotal moment: 30% of new drugs will be AI-discovered by 2025, yet 42% of clinical trials still hemorrhage budgets

The Intelligent Future: Bravura-AI’s Vision for Limitless Industrial Automation

1. Industry 4.0: Automation on the Rise Industry 4.0 is redefining manufacturing through AI, cloud, and advanced robotics. The global industrial automation market size is

How Bravura-AI Fuels Sustainable Growth in Process Industries: Driving Toward Net-Zero

1. Why Sustainability Must Be Strategic Manufacturing and heavy industry remain major contributors to global energy use and CO₂ emissions—accounting for nearly three-quarters of energy-related

Bravura-AI’s Role in Industrial Cybersecurity: Fortifying the Digital Frontier

1. The Rising Threat Landscape in Manufacturing As Industry 4.0 advances, the convergence of Information Technology (IT) and Operational Technology (OT) systems is exponentially expanding cyber

Bridging the Skills Gap: How Bravura-AI Empowers the Modern Manufacturing Workforce

1. Introduction: A Workforce in Short Supply and Rising Risk The global manufacturing sector is entering a critical phase. As the experienced workforce retires and

Ensuring Excellence: Bravura-AI’s Role in Enhancing Quality and Compliance Across Manufacturing

1. Introduction: When Quality Is Not Optional In regulated industries like pharmaceuticals, medical devices, and food production, quality control and compliance are not competitive advantages—they

Proactive Operations: How Bravura-AI Boosts Efficiency by Connecting Data Silos

1. Introduction: The Real Cost of Data Fragmentation In today’s industrial operations, unexpected equipment failures and unplanned downtime can be devastating. But just as costly

Turning Commissioning Chaos into Predictability: PlantUnity’s Proven Path to 50% Faster Execution

The $1M-Per-Day Stakes of Commissioning For plant managers, commissioning is the ultimate stress test. Every hour of delay costs heavily—up to $1.5 million daily

The Agentic Imperative: How Bravura-AI is Unlocking Industrial Autonomy for Process Industries

The Intelligence Gap: Process Industries at a Crossroads 1. Beyond Chatbots: The Radical Leap to Agentic AI Agentic AI represents a paradigm shift, moving from reactive

Shattering the Digital Berlin Wall: How Bravura-AI’s Plant Unity Unifies IT/OT to Unleash Industrial Potential

The Great Divide: When Silos Cripple Industrial Competitiveness For decades, a silent war raged within industrial facilities. On one side: Information Technology (IT) — guardian

Beyond the Data Deluge: How Bravura-AI is Unlocking $4.4 Billion in Trapped Value for Chemical & Process Industries

The $4.4 Billion Albatross: The Crushing Weight of Industrial Data InefficiencyThe chemical, petrochemical, pharmaceutical, and advanced materials industries form the bedrock of modern civilization. Yet,

Empowering the Human Element: Workforce Evolution in the AI Era

The manufacturing sector is in the midst of a significant transformation, driven by digital adoption and evolving workforce demands. With an aging workforce and a

AI in Pharma: Revolutionizing Quality Control and Regulatory Compliance

The pharmaceutical and medical device industries operate under stringent regulations, where product efficacy, safety, and compliance are paramount. Artificial intelligence (AI) is proving to be

Accelerated Projects: How AI is Revolutionizing Commissioning and Decommissioning

Complex industrial projects like commissioning new facilities or decommissioning old ones are typically resource-intensive, time-consuming, and prone to human error. However, with the integration of