The $4.4 Billion Albatross: The Crushing Weight of Industrial Data Inefficiency

The chemical, petrochemical, pharmaceutical, and advanced materials industries form the bedrock of modern civilization. Yet, beneath the hum of reactors and the flow of pipelines, a silent crisis bleeds profitability: an estimated $4.4 billion lost annually to operational inefficiencies. This isn’t just a number; it’s the cumulative cost of delayed startups, unplanned downtime, suboptimal yields, energy waste, quality deviations, and reactive maintenance – all symptoms of a deeper malaise: the catastrophic failure to harness the data these industries generate.

For decades, these sectors have invested heavily in automation, sensors (IoT), and control systems. SCADA, DCS, PLCs, LIMS, MES, ERP – the alphabet soup of industrial software generates torrents of data. Yet, paradoxically, this wealth of information has become a burden. Why? Because it’s:

- Disaggregated: Scattered across dozens of isolated systems – control rooms, lab databases, maintenance logs, supply chain platforms, engineering documents (P&IDs, PFDs). Finding the right data point is like searching for a specific grain of sand on a beach.

- Non-Uniform: Data formats and semantics differ wildly. A temperature reading from a DCS might be “TIC-101.PV,” while the maintenance system calls it “Reactor Inlet Temp,” and the process engineer’s spreadsheet labels it “Rxn Temp Feed.” Reconciliation is manual, error-prone, and time-sucking.

- Decontextualized: Raw data points lack meaning. A pressure spike is just a number without knowing the valve position, feedstock composition at that moment, or the maintenance history of the pump upstream. Context is trapped in tribal knowledge or buried in PDF reports.

- Cybersecurity-Locked (and Siloed): Essential security protocols, while non-negotiable, often create formidable barriers between systems. Data needed for optimization might reside in a highly secure control network, utterly inaccessible to the analytics team or supply chain planners operating on the corporate network. Data becomes stranded.

The Consequence: Decision Paralysis and Costly Guesswork

This data chaos has profound operational impacts:

- Slow Troubleshooting: Diagnosing a process upset can take hours or days, as engineers manually collate data from multiple sources, often via screenshots and spreadsheets. Downtime costs escalate exponentially.

- Suboptimal Operations: Running plants “by feel” or based on outdated operating procedures because real-time optimization is computationally impossible with fragmented data. Energy consumption creeps up, yields dip.

- Ineffective Maintenance: Reactive instead of predictive. Equipment fails unexpectedly because condition monitoring data isn’t integrated with operating context and historical failure modes.

- Painful Reporting & Audits: Generating regulatory reports, sustainability metrics (like carbon footprint), or even routine performance summaries requires massive manual effort, pulling data from multiple incompatible systems.

- Innovation Bottleneck: Scaling new processes, implementing digital twins, or deploying advanced process control (APC) is hampered by the lack of a clean, unified, contextualized data foundation.

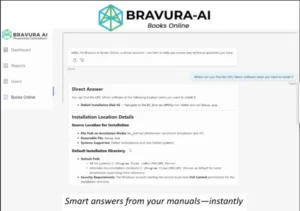

Enter Bravura-AI: Not Just Another Dashboard, But a Foundational Data Nervous System

This is where Bravura-AI steps in, not with a point solution plastering over symptoms, but with a fundamental re-architecting of industrial data management. Their mission is clear: Liberate stranded data and transform it into contextualized, actionable intelligence for superior decision support and documentation.

Core Innovation: Plant Unity – The Foundational Data Fabric

Bravura-AI’s flagship, Plant Unity™, isn’t just another data historian or visualization tool. It’s a purpose-built semantic data layer designed explicitly for the complexity of process industries. Think of it as the central nervous system for plant data:

- Unification Engine: Plant Unity ingests data from everywhere – real-time streaming data (OPC UA, MQTT), static databases (SQL, NoSQL), files (PDFs, Excel, P&IDs), and even legacy systems. It doesn’t just collect; it understands the relationships. Crucially, it preserves relational information. It knows that “TIC-101.PV” in the DCS is the “Reactor Inlet Temp” in the maintenance log is the tag referenced on P&ID-101. This contextual mapping is revolutionary.

- Semantic Standardization: Plant Unity applies a powerful ontology (a formal framework defining concepts and relationships) specific to process industries. It automatically tags and classifies incoming data, resolving synonyms and ambiguities. This creates a single source of contextual truth. A pressure reading is no longer just a number; it’s instantly linked to the specific equipment, process unit, material stream, and relevant operating limits.

- Cybersecurity-Aware Integration: Plant Unity is designed to operate within complex industrial security landscapes (ISA/IEC 62443 zones and conduits). It can securely bridge the gap between OT (Operational Technology) and IT networks, acting as a controlled conduit for contextualized data without compromising the integrity of critical control systems. Data moves securely where it needs to go.

- Future-Proofing via Decoupling: By creating this unified semantic layer, Plant Unity decouples applications from underlying data sources. Need to replace your old historian? Migrate your MES or update your DeltaV version? With Plant Unity as the intermediary, the applications relying on contextualized data (like Bravura’s own AI tools or third-party analytics) are largely unaffected. This eliminates vendor lock-in and drastically simplifies future IT/OT evolution.

From Stranded Data to Strategic Advantage: The Generative AI Catalyst

Plant Unity provides the essential foundation. Bravura-AI’s Generative AI (GenAI) applications are the powerful engines that turn this high-quality, contextualized data into tangible business value, focusing on two critical pain points: Decision Support & Documentation.

Revolutionizing Decision Support:

Imagine an engineer facing a sudden drop in yield:

- Old Way: Manually query DCS historian, check LIMS for lab results, search maintenance logs for recent work, dig through P&IDs, consult SOPs, call colleagues. Hours pass.

- Bravura-AI Way: Using a natural language interface powered by GenAI: “Show me all process parameters, lab results, maintenance events, and operating procedures for Reactor C-201 around the time yield dropped 15% yesterday afternoon.” Plant Unity instantly retrieves all relevant, contextualized data from across systems. The GenAI engine synthesizes this information, highlights correlations (e.g., “Yield drop coincided with a pump vibration alarm and a slight shift in feedstock impurity levels”), and suggests probable causes and recommended actions based on historical patterns and process knowledge. Decision time slashed from hours to minutes.

Key Features Enabling This:

- Intelligent Data Filtering & Summarization: GenAI cuts through the noise. Instead of raw data dumps, it delivers concise summaries, focusing only on the information relevant to the specific query or anomaly. “Optimizing reports by filtering out unnecessary information” becomes dynamic and contextual.

- Visual Context Integration: GenAI leverages Plant Unity’s understanding of the plant’s physical and logical structure. It can generate visualizations overlaying key data directly onto P&IDs or 3D models (“Visualize configuration data using process design”). Seeing a temperature trend on the specific pipeline or vessel provides immediate, intuitive understanding.

- Predictive Scenario Modeling: Beyond diagnostics, GenAI can simulate “what-if” scenarios based on current contextualized data and historical patterns. “What happens to energy consumption if I increase throughput by 5%?” “What’s the optimal catalyst regeneration schedule based on current deactivation rates and predicted feedstock changes?”

Transforming the Documentation Nightmare:

Compliance, safety, training, and knowledge transfer rely heavily on accurate, up-to-date documentation. Yet, keeping P&IDs, SOPs, operating manuals, and training materials synchronized with actual plant configurations and procedures is a Herculean, error-prone task.

- Bravura-AI’s GenAI: Automates the creation and updating of critical documentation directly from the contextualized data in Plant Unity.

- Auto-Generated SOPs: Drafts standard operating procedures reflecting actual current best practices and equipment configurations, pulling data from control logic, valve sequences, and approved operational boundaries. Reduces drift and ensures consistency.

- Dynamic P&ID Updates: Flags discrepancies between the “as-built” plant data (sensor tags, valve positions) and the official P&ID drawings, suggesting updates. Maintains drawing accuracy.

- Intelligent Audit Trails: Automatically generates comprehensive, contextualized audit trails for regulatory submissions or internal reviews, pulling data from across systems and explaining anomalies coherently.

- Personalized Training Materials: Creates role-specific training modules based on actual plant data and procedures, accelerating onboarding and reducing operator error.

- The Equipment Dossier: create a dossier before arriving on-site for a maintenance or troubleshooting task and have all information in hand to ensure you are master of the situation upon arrival.

The AVEVA Imperative and Bravura-AI’s Strategic Alignment

AVEVA, a global leader in industrial software, rightly emphasizes that robust data infrastructure is non-negotiable for modern industrial operations. Their vision hinges on:

- Real-Time Collaboration: Enabling geographically dispersed experts (process engineers, maintenance, suppliers) to work on the same contextualized data set simultaneously during critical events.

- Optimized Feedstock Sourcing: Integrating market data, logistics, inventory levels, and real-time plant consumption/performance data to make dynamic, cost-optimal purchasing decisions.

- End-to-End Traceability: Tracking materials, energy, and carbon footprint from raw material source through processing to final product, essential for sustainability reporting and quality control.

Bravura-AI’s Plant Unity is the enabling layer that makes AVEVA’s vision operationally achievable. Plant Unity provides the secure, contextualized, unified data stream that AVEVA’s applications (PI System, Unified Operations Center, etc.) require to deliver their full potential in a complex, multi-vendor environment. Bravura doesn’t replace AVEVA; it empowers it by solving the foundational data chaos that hinders even the best applications.

The Tangible Bottom Line: From Cost Center to Profit Driver

The impact of Bravura-AI’s approach isn’t theoretical; it translates directly to the balance sheet by attacking the root causes of the $4.4 billion inefficiency:

- Massive Man-Hour Savings: Eliminating 50-80% of the time engineers spend hunting for data, reconciling sources, and generating reports. Freeing up highly skilled personnel for true optimization and innovation.

- Reduced Downtime: Faster troubleshooting and diagnostics cut Mean Time To Repair (MTTR) by 30-60%. Predictive insights prevent catastrophic failures.

- Improved Yield & Quality: Contextualized optimization identifies subtle process deviations impacting yield or product specs, enabling real-time corrections. 1-3% yield improvements are common and hugely valuable at scale.

- Lower Energy Costs: Optimized operations based on comprehensive contextual data reduce energy waste by pinpointing inefficiencies in heating, cooling, and compression.

- Reduced Operational Risk: Fewer human errors in procedures, better compliance through automated documentation, and improved safety through faster, more accurate situational awareness.

- Accelerated Innovation: A reliable, contextualized data foundation enables rapid deployment and scaling of advanced applications like digital twins, machine learning models, and closed-loop optimization.

Beyond Efficiency: Enabling Sustainable Growth

In an era demanding sustainability and agility, Bravura-AI’s technology is transformative. Accurate carbon accounting requires tracing energy and material flows across integrated systems – impossible without Plant Unity’s contextualization. Responding to volatile markets or feedstock availability demands real-time operational flexibility powered by integrated, contextualized data and AI-driven scenario planning. Bravura-AI doesn’t just fix the past; it unlocks the future.

Conclusion: The Indispensable Foundation for Industry 4.0

The chemical and process industries stand at an inflection point. The $4.4 billion inefficiency tax is unsustainable. While investments in AI and analytics are crucial, they will fail without addressing the fundamental data fragmentation and contextual void. Bravura-AI, with its Plant Unity semantic data layer and targeted GenAI applications, provides the indispensable foundation.

It’s not about adding more technology; it’s about finally making sense of the technology already there. By centralizing, standardizing, and – most critically – contextualizing industrial data, Bravura-AI unlocks trapped value, empowers human expertise, and paves the way for truly intelligent, efficient, and sustainable operations. The revolution isn’t coming; it’s here, built on a foundation of unified, intelligent data. The question for industry leaders isn’t if they need this capability, but how quickly they can deploy it to stop the bleeding and capture the immense opportunity.