In 2024, we embarked on a project that felt like the culmination of years of innovation and collaboration. It was our third time working with BP, but this time, the stakes were higher, and the focus was sharper: technology-driven efficiency. The goal? To transform the commissioning process for a new facility using digital tools, ensuring accuracy, saving time, and staying within budget. What unfolded was a story of teamwork, innovation, and the power of digital solutions.

The Backstory

Our first collaboration with Accenture and BP was all about people—getting the right team in place. The second project with a local integrator on behalf of BP brought people and technology together, laying the groundwork for what was to come. By the time the third project rolled around, it was clear: this was our chance to fully embrace digital innovation and show what was possible when technology took the lead.

The challenge was straightforward but daunting. We were given a mountain of technical documentation—Cause & Effect (C&E) matrices, instrument indexes, I/O layouts, and a copy of the automation system configuration database. Our task? Use this data to prepare everything needed for commissioning, ensuring every instrument was linked to the right control module, every step was documented, and every safety rating was verified. And we had to do it mostly remotely, with tight deadlines and an even tighter budget.

The Turning Point

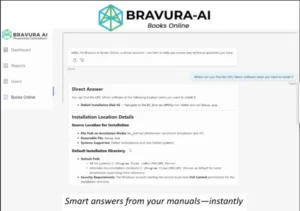

Enter Smart Completions (a Hexagon software product) and Bravura AI Plant Unity, our digital commissioning solution. These tools became the heroes of our story. Instead of manually sifting through documents and risking human error, we used these platforms to automate the process. We populated the commissioning database, linked instruments to control modules, and identified the necessary commissioning steps—all with a level of precision and speed that manual methods simply couldn’t match.

One of the most exciting moments came when we tackled the C&E matrix. Traditionally, this would have been a manual, time-consuming process. But with Plant Unity, we were able to break it down systematically, laying the groundwork for a future feature that would automate this step entirely. It was a glimpse into the future of commissioning—one where technology handles the heavy lifting, and humans focus on oversight and strategy.

The Human Touch

While technology was at the heart of this project, the human element was just as critical. Our team worked tirelessly to ensure every detail was perfect. Senior experts stepped in to provide oversight, adding an extra layer of quality assurance. And because we knew how important it was to make life easier for our clients, we prepared print packages—ready-to-use documents that saved them time and effort.

The result? What could have taken 8 man-weeks was completed in just 4. We didn’t just meet the budget; we came in under it. And perhaps most importantly, we delivered a solution that was error-free and ready to go.

The Client’s Perspective

The Accenture project manager put it best:

“It is such a great contrast with the recent past, where the stress consisted of concerns for the deadlines, budget, and keeping track of all the various tasks. Everything is handled with great efficiency, a very low risk of errors, and easily within appointed timelines and budget. All project managers would be extremely pleased to experience such an improvement of circumstances for their role.”

Hearing this feedback was a reminder of why we do what we do. It’s not just about delivering a project; it’s about making a real difference for our clients.

Why This Matters

This project wasn’t just a win for us, Accenture, or BP—it was a win for the entire industry. It showed how digital tools like Plant Unity can revolutionize processes that have traditionally been time-consuming and error-prone. And it’s not just about oil and gas. The lessons we learned here can be applied to chemicals, mining, and any industry that relies on continuous process manufacturing.

The Bigger Picture

What made this project so special wasn’t just the technology or the results—it was the collaboration. Working with Accenture and BP, we pushed the boundaries of what was possible. We proved that with the right tools, the right team, and the right mindset, even the most complex challenges can be tackled efficiently and effectively.

As I reflect on this project, I’m reminded of how far we’ve come—and how much further we can go. This is just the beginning. The future of commissioning is digital, and we’re excited to be at the forefront of this transformation.

A Call to Action

If you’re facing similar challenges in your industry, let’s talk. Whether it’s oil and gas, chemicals, mining, or beyond, there’s a digital solution that can transform your processes and deliver real results. Let’s write the next chapter of this story together.

What’s your take on the role of digital tools in industrial projects? Have you seen similar transformations in your field?