The Great Divide: When Silos Cripple Industrial Competitiveness

For decades, a silent war raged within industrial facilities.

On one side: Information Technology (IT) — guardian of enterprise systems (ERP, CRM, SCM), corporate networks, and business analytics.

On the other: Operational Technology (OT) — master of the physical world: DCS, SCADA, PLCs, sensors, actuators, and the plant floor.

Separated by culture, tech, and cybersecurity (Air Gap, DMZ), these domains evolved apart — creating costly data silos.

The Strategic Liability of Siloed Operations

1. The Blind Spot Problem

Without unified data, decision-makers operate with partial insights.

- Supply planners lack real-time plant data.

- Maintenance can’t align vibration data (OT) with inventory (IT).

- Process engineers optimize in isolation, unaware of bottlenecks.

Result: reactive and suboptimal decisions.

2. The Velocity Killers

Data friction kills speed.

- Quality issues take hours to trace across LIMS, DCS, MES, and logs.

- Forecasting is done on stale data.

Result: slower response, missed opportunities.

3. The Innovation Tax

New technologies like AI, APC, and digital twins need cross-domain data.

- Custom integration cost becomes prohibitive.

Result: transformation stalls.

4. The Compliance Nightmare

Regulations demand end-to-end traceability.

- Stitching IT and OT data manually is error-prone.

Result: audit risks and inefficiency.

5. The Talent Drain

Skilled workers spend 50% of time on data wrangling.

Result: low morale, high turnover.

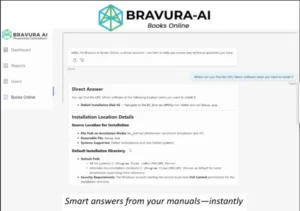

Bravura-AI’s Core Mission: Architecting Unity from Chaos

Bravura-AI doesn’t just integrate IT/OT — it eliminates silos.

Its goal: Make all operational data accessible, rich in context, and ready for action through Plant Unity™.

Plant Unity: Beyond Integration, A Unified Data Fabric

1. Centralization: A Single Source of Truth

- Challenge: Data lives in ERP, DCS, PDF P&IDs, sensors, LIMS, etc.

- Solution: Plant Unity connects to anything — OPC, MQTT, SQL, REST, documents — keeping data intact.

- Impact: Access everything from one query, instantly.

2. Standardization: Order in Data Chaos

- Challenge: Same sensor, many names.

- Solution: Industry-specific ontology maps data with meaning, location, ownership, and relationships.

- Impact: Machine-readable structure enables automation and consistency.

3. Optimization: From Noise to Signal

- Challenge: Raw industrial data is messy.

- Solution: Context-aware filters, derived metrics, and smart linking clean and enrich the data.

- Impact: Only relevant, actionable info reaches engineers.

4. Visualization: Context is King

- Challenge: Dashboards lack context.

- Solution: Data Management & Composure (DMC) Environment gives visualized, contextual analytics. Chatbot provides natural-language access to live plant insights.

- Impact: Faster decisions with deeper understanding.

5. Automation: Freeing Human Capital

- Challenge: People waste time on reports and lookups.

- Solution: Auto-generate reports, trigger workflows, sync docs with real data.

- Impact: Skilled teams focus on value-added work.

Tangible Results: Silo-Free Success

- 40–70% Faster Decisions

- 2–5% Yield Gains, 5–15% Energy Savings

- 10–30% Less Downtime

- 60–80% Automated Reporting

- Faster Regulatory Compliance

- Future-Proof Integration Architecture

Unified Operations Center: What It Looks Like

Imagine a real-time digital control center where:

- Operations Managers see live process and cost data overlayed.

- Maintenance gets AI-generated work orders.

- Engineers simulate changes with real-time twins.

- Planners adjust orders with actual plant rates.

This is possible now — with Plant Unity.

Conclusion: Unity is the New Imperative

IT/OT silos are no longer acceptable.

Bravura-AI’s Plant Unity delivers a secure, unified, and contextualized data fabric.

It turns fragmented data into a strategic weapon.

From energy to pharma, the future belongs to those who unify.

The future of industry is unified. Are you building it?