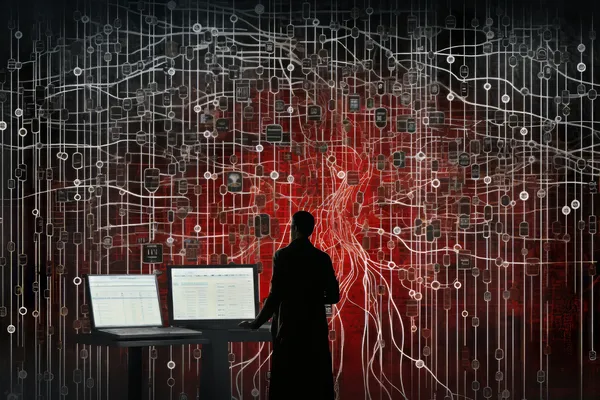

For generative AI to be truly effective in process manufacturing, the foundational data issues must be resolved first. The problem isn’t a lack of data; it’s that this data is often disaggregated, non-uniform, lacking context, and trapped in isolated “islands of automation”. Without addressing these issues, AI cannot deliver actionable insights or enable true automation.

Bravura AI’s Plant Unity is specifically designed to tackle this challenge head-on, serving as the “gateway to Agentic AI”. It provides a foundational model by unifying system design and engineering data. Plant Unity achieves this through five key steps:

• Centralization: Bringing all static and streaming data into a single location while preserving relational information, creating “one source of truth”.

• Standardization: Storing data in a consistent format that removes dependency on a single system, preparing it for migrations and ensuring reliability by reducing misinterpretation and human error.

• Optimization: Filtering out unnecessary information, resolving dynamic and dead references, and scrubbing orphaned objects to present only the most relevant data.

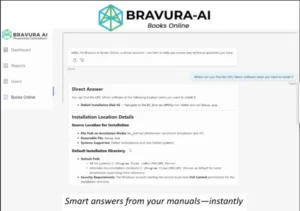

• Visualization: Converting complex configuration and process data into intuitive visualisations, offering crucial insights and context.

• Automation: Automating repetitive reporting tasks, freeing up expensive skilled staff for higher-value analysis and strategy, and significantly reducing manual errors and costs.

By transforming data into knowledge and insights at a lower cost and with fewer mistakes, Plant Unity lays the groundwork for powerful AI applications, paving the way for a more intelligent and efficient industrial future.